DESCRIPTION OF SHIELDING MATERIALS AND SHIELDING EFFICIENCY

Magnetic induction mitigation is achieved by applying magnetic shielding produced by coupling two different materials:

- A material with high electrical conductivity

- A material with high magnetic permeability

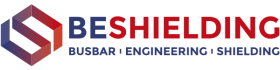

In the presence of a variable magnetic field (inductor field), the layer of material with high electrical conductivity becomes the site for circulating currents and these, in turn, generate a reaction magnetic field (inductive field). The combined effect of the fields — inductive and inductor — produces an overall reduction in the total magnetic field.

The layer of material with high magnetic permeability makes it possible to reduce magnetic induction by absorbing the magnetic field present. Its shielding behaviour — which like an “umbrella” protects against the magnetic field — can be very intense close to the shield but tends to wane the further away from the shield one gets.

The combination of the two materials — ferromagnetic and conductive — produces a shield with excellent shielding properties both when close to the shield, thanks mainly to the ferromagnetic component, as well as at a distance from the screen, thanks to the conductive component.

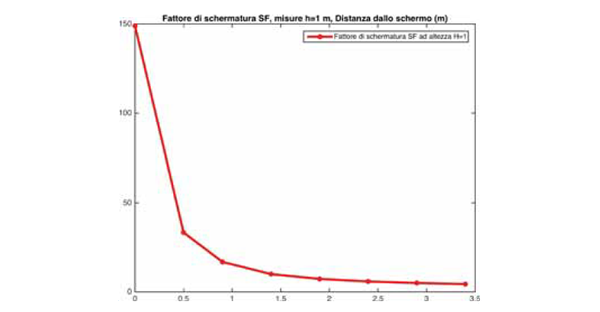

Shielding efficiencies are defined by measuring the shielding factor (SF) performed at the BEShielding S.r.l. research and development laboratory in via Ferrero 10, Rivoli (TO), Italy.

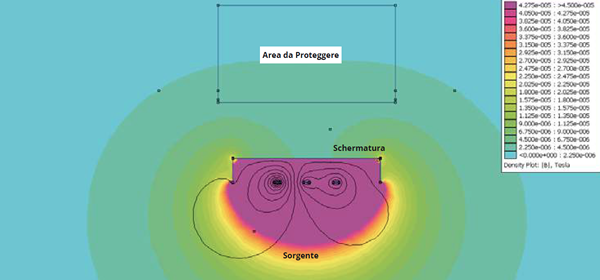

The tests were carried out by measuring the magnetic induction values emitted by a 630 kVA resin transformer before and after the field mitigation intervention.

The shield dimensions are adapted to the size and consequently the dimensions of the transformer installed.

The dimensions of the partition subjected to the experimental tests are given as an example.

The shielding factor proposed below is calculated as the ratio of the magnetic induction modules pre- and post-shielding as a function of distance from the shield.

It represents a simple, immediate indication of how many-fold the magnetic induction value can be reduced by application of the shielding solution.

Fig. 20 – Effect of shielding displaying the magnetic induction levels in the area to be protected

Fig. 21 – Test layout for determining the shielding factor

Fig. 22 – Shielding solution dimensions

Fig. 23 – Development of the shielding factor as a function of the distance from the shield at a height of 1 m above ground.